No products in the cart

Gen 3 Basics: Schematic and Components

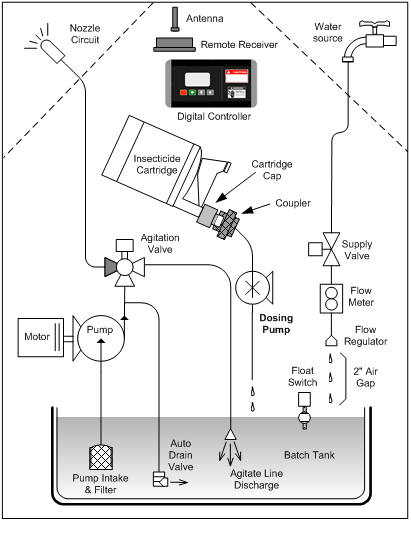

The operations of the Gen III+ are managed by a digital controller and a number of electro-mechanical components. Information about mist schedules, duration, dosing and agitating the insecticide are entered into the controller by the user.

Components – Interface and Controls

- Digital Controller – accepts user input, displays unit operating mode and status, controls electromechanical components.

- Remote Receiver & Antenna – receives signal from handheld remote transmitter. Receiver located on underside of enclosure lid.

- LED warning light – annunciates unit status – warning, misting, suspended due to error or empty cartridge. Located on top of enclosure lid.

Components – Fresh Water Flow Control

- Supply Valve – opens to allow water to flow from faucet into batch tank.

- Flow Meter – on inlet water line, measures flow into the batch tank. Used to control insecticide dosing and error condition calculations.

- Float Switch – closes supply valve when batch tank is full.

- Flow Regulator – ensures smooth flow of water into batch tank. Positioned to ensure 2” air gap between water supply and batch tank contents.

Components – Insecticide Flow Control

- Insecticide Cartridge –vented two-chamber bottle containing one of a number of concentrated insecticides. This manual uses the word “bottle” interchangeably with “cartridge.”

- Bottle Cap – enables secure connection to snap-in coupler.

- Coupler – accepts snap-in cap.

- Dosing Pump – precisely meters insecticide concentrate from the cartridge into the batch tank.

Components – Agitation and Atomization

- Batch Tank – 2 gallon plastic tank with enough capacity to enable a 120 nozzle circuit to mist for 120 seconds.

- Pump & Motor – atomizes batch tank contents through nozzle circuit. Pump pressure typically set to 240 psi.

- Agitation Valve – One path through the valve routes fluid to the nozzle circuit. The other path recirculates fluid in the batch tank through the agitation line. Each mist (including REMOTE MISTs, if remote agitation duration > 0) will be preceded by an agitation cycle that will ensure thorough mixing of the batch tank contents prior to misting. In addition, there is a once daily agitation that is independent of any AUTO or REMOTE MIST. The agitating valve also eliminates the possibility of a siphon emptying the batch tank contents.

- Pump Intake Line and Filter – Pump intake positioned near bottom of batch tank. Filter ensures debris is not drawn into pump and nozzle circuit.

- Agitation Line – during agitation, batch tank contents are recirculated to ensure thorough mixing prior to misting.

- Auto-Drain Valve – ensures rapid increase in nozzle circuit pressure on pump startup and rapid decrease on shutdown.

Components – Structural

- Enclosure and Lid – sturdy powder-coated aluminum walls, locking lid, and aluminum chassis and feet.

- Shroud – black plastic inner shelf with well for snap-in insecticide cartridge. Supports recessed controller and pressure gauge.

Other Components

- Remote Transmitter – 3-button remote enables the user to start a mist, stop a mist and skip the next scheduled mist.

- Key – for lock that is located on top front wall of enclosure.